Led lighting is becoming increasingly popular in both homes and businesses, and one of the most popular led lighting solutions is the led strip light. But why does the LED strip need an aluminium profile? In this article we will go through the characteristics of LED strips, the importance and technical calculation of aluminium profiles and the different aluminium profile options. Finally, we give advice on the choice of LED strip and aluminium profile.

Features of Led strip lighting

Led strip lights are popular for many reasons. They are energy efficient, flexible and offer a versatile lighting solution. Let’s take a closer look at these features.

Light output and energy efficiency

Led strip lighting has excellent light output and energy efficiency compared to traditional lighting methods. They consume less energy and produce more light at the same time.

Flexibility and adaptability

Led strip lights are flexible, so they can be installed in a wide variety of locations and shapes. They are also easy to cut and join, allowing for versatile lighting solutions.

Colour temperature and light tone

Led strip lights come in a wide range of colour temperatures and light tones, so you can choose just the right mood and look for your space.

Why does an LED strip light need an aluminium profile?

Aluminium profiles are important in the use of led strips for many reasons. Here we go through the most important ones.

Heat management

Although LED strips produce less heat than traditional luminaires, they still heat up when in use. The aluminium profile acts as an efficient cooling solution, as it conducts heat away from the LED strip and extends its lifetime.

Ease of installation

Aluminium profiles make the installation of LED strips quick and easy. They provide a fastening solution that holds the tape in place while protecting it from mechanical damage.

Longer lifetime

How long will the led strips last? 50,000 hours when well cooled. As mentioned earlier, the aluminium profile allows the LED strip to get rid of excess heat, which prolongs its lifetime. In addition, the aluminium profile protects the tape from dust, moisture and other environmental factors.

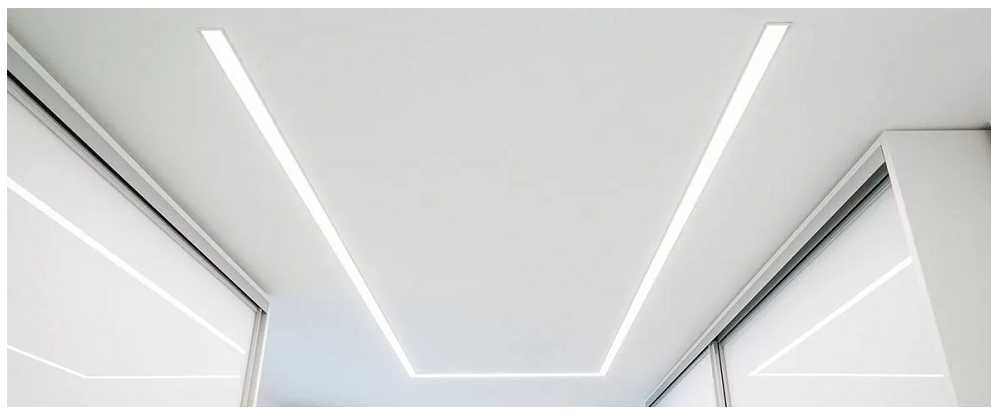

Aesthetic appearance

The aluminium profiles give the LED strips a neat and professional look. They hide the tape and wires, giving a neat and stylish finish.

What happens to the LED strip light if it gets too hot?

One reason why an LED strip light needs an aluminium profile is for cooling, but what happens to the LED strip light if it gets too hot? The Led strip light will be destroyed more quickly. People still often ask whether an LED strip light needs aluminium or some other heat management medium. So yes it does, otherwise the LED strip light will not last long. This is also affected by the power of the LED strip light and the more powerful the LED strip light, the more heat it produces.

Led lightstrip light to change colour

The first thing you notice when the LED strip light gets too hot is the change in colour of the LED strip light.

Led lightstrip goes out

Another thing you will notice is that the LED lights go out from the LED strip light.

Led light strip hardens

The third thing is that, the LED strip of light hardens and turns yellow.

Different materials for the thermal management of LED strip lighting

Why does an LED strip light need an aluminium profile, why not a plastic strip? It is a good idea to glue the LED strip light to a solid heat-conducting material. Thermal conductivity varies between metals and is generally higher the higher the melting point of the metal.

For example, refractory metals such as niobium, molybdenum and tungsten are very good thermal conductors, but no one makes a mounting base for an LED strip light.

The shape and surface area of the metal also affects the heat transfer capacity, which is why in many cases the heat sink of LED lights is not just a flat lump, but has wings.

Thermal conductivity is measured in m-k.

What does m-K stand for? m-K stands for metres Kelvin. It is a unit of measurement of thermal conductivity. Thermal conductivity tells you how much heat energy is transferred through a substance per unit length during a unit temperature difference. The higher the thermal conductivity, the better the material conducts heat.

Use of aluminium as a material for LED profiles

Aluminium is the most common material used in the manufacture of LED profiles. It is durable, lightweight and easy to work with, even with a wood saw. In addition, aluminium is reasonably priced.

The melting point of aluminium is about 660 °C. The thermal conductivity is about 200 W/(mÂ-K)

Aluminium also has excellent thermal conductivity, which helps to remove heat from the LED light. Aluminium-based LED profiles are generally more efficient at heat control than other materials, and their use can lead to longer LED light life.

Use of copper as a material for LED profiles

Copper is another material used in the manufacture of LED profiles. Copper has excellent thermal conductivity, which helps to remove heat from LED light.

The melting point of copper is about 1085 °C. It has a thermal conductivity of about 390 W/(mÂ-K), which makes it a very good thermal conductor.

Copper-based LED profiles are therefore very efficient in heat control compared to other materials, but expensive. Copper is only found in more specialised whales.

Use of steel as a material for LED profiles

Steel is also used as a material for LED profiles. Steel has reasonable thermal conductivity, but it is not as efficient at controlling heat as aluminium and copper.

The melting point of steel varies for different steel alloys, but is generally between 1400 and 1600 °C. The thermal conductivity also varies between different steel alloys, but is generally between 15 and 50 W/(mÂ-K)

However, steel-based LED profiles can be used in situations where durability and strong protection are required, but where heat dissipation is not a major concern, for example outdoors.

Use of plastic as a material for LED profiles

Plastic is light, cheap and easy to work with, but it has significantly lower thermal conductivity than other materials. You will see some form of mounting gutters or L-shaped corner strips installed.

The melting point of plastics varies for different types of plastic, but is generally below 300 °C. Thermal conductivity is usually very low, below 1 W/(mÂ-K).

Plastic-based LED profiles are not recommended in any situation for thermal management. The use of plastic profiles should only be considered in situations where heat dissipation is of no importance, such as in cold conditions. Plastic profiles are very affordable.

Led strip light cooling theory

Heat output

The thermal power produced by a Led strip light is the difference between its electrical power and its luminous power. The electrical power is the power consumption per watt of the LED strip and the light output is the luminous flux per lumen of the LED strip divided by 683.

For example, a 14.4W LED strip consumes 14.4 watts per metre and produces about 100 lumens per watt. In this case, its electrical power is 14.4 W and its luminous intensity is 0.146 W (100/683). Thus, its thermal output is 14.253 W (14.4-0.146) per metre.

An aluminium profile is a good choice for cooling LED strip, as aluminium is a very good heat conductor. The required length of an aluminium profile depends on its thickness, cross-section and thermal conductivity, as well as the heat output of the LED strip.

Thermal conductivity

Thermal conductivity is a property of a material that describes how well it transfers heat energy. Aluminium has a thermal conductivity of about 200 W/(mÂ-K), which means that a one-metre-long piece of aluminium with a cross-section of one square metre will transfer approx. 200 watts of thermal power when there is a temperature difference of one kelvin between its ends.

Evaporation of heat

To calculate the evaporation of heat, you also need to know the thermal conductivity of aluminium (about 200 m-K) and the convection coefficient of air. These are physical properties that tell you how well heat is transferred from aluminium to air.

The total convection coefficient is not easy to calculate, but you can use estimates for different situations. For example, if the air flow rate is 1 m/s and the humidity is 50%, you can use:

U = 10 W/m2 K

You can use the following formula to estimate the heat dissipation capacity of an aluminium profile:

- P = U * A * Î “T

- P is the heat dissipation rate in watts

- U is the total convection coefficient in watts per square metre per degree

- A is the effective area of the aluminium profile in square metres

- Î “T is the temperature difference in degrees between aluminium and air

For example, take a shallow U profile that is 2 mm thick and has U-side dimensions of 8 + 18 + 8 mm = 34 mm.

That is, a 34 mm wide and 2 mm thick aluminium profile has an effective surface area of about 0.072 m2 per metre (not taking into account the shape of the profile).

If the temperature difference produced by an LED strip is 30°C (for example, 54°C for an LED strip and 24°C for air), you can calculate the heat dissipation capacity of aluminium as follows:

- P = U * A * Î “T

- P = 10 * 0.072 * 30

- P = 21.6 W

This means that a one metre long aluminium profile can dissipate up to 21.6 W of thermal energy under ambient conditions.

By comparison, LED strip lighting produces 14.4 W/metre, less than what aluminium can dissipate.

This suggests that this aluminium profile is sufficient to keep the same LED strip cool.

So the wider and thicker the aluminium profile is, the shorter it can be to cool the LED strip. This is because a wider and thicker aluminium profile transfers heat energy more efficiently by both conduction and convection.

Different types of aluminium profiles

Aluminium profiles are available in a wide range to suit different installation sites and needs. Here we present some of the most common types of profiles.

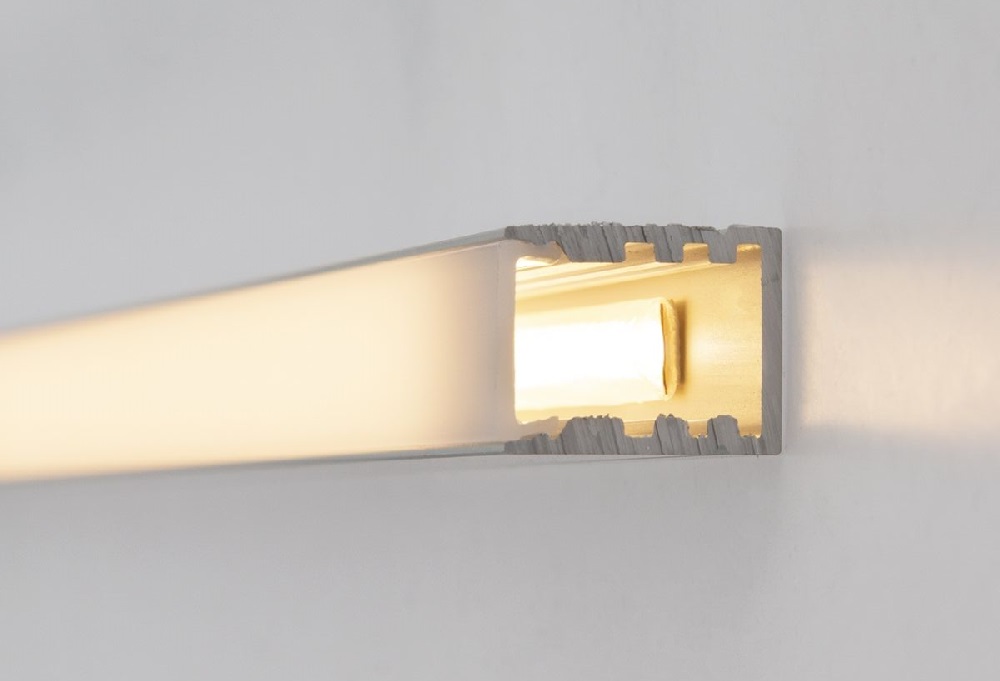

Surface-mount profiles

Surface mount profiles are ideal for applications where the LED strip is to be mounted directly on the surface. They are easy to install and available in different shapes and sizes. AND because the profile is surface mounted and has its own brackets, all surfaces of the aluminium are cooler.

Recessed profiles

Recessed profiles are designed for installation in structures such as walls or ceilings. They give the lighting a recessed and unobtrusive appearance. For submersible profiles, remember that they usually use lower power LED strips, as they are only visible as wings in free air space.

Corner profiles

Corner profiles are particularly suitable for applications where the LED strip is to be installed on a corner or curved surface. They provide a neat solution for even the most difficult of jobs. If the corner profile stays off the surfaces by a few millimetres, it cools well, or if the corner profile is made into a pendant, it acts as a radiator on all surfaces and several LED strip can be installed.

Choice of Led strip and aluminium profile

When choosing between LED strip and aluminium profile, it is important to consider the following:

The needs of the project

Think about what kind of lighting you need and where the LED strip should be installed. This will help you choose the right type of LED strip and aluminium profile.

Budget

Led strips and aluminium profiles vary in price. Define your budget and compare different options to find the best solution for your needs. For aluminium profiles, the mass directly affects the price. A bigger profile is worth more.

Installation site

The installation location will determine which aluminium profile is most suitable. We will now look at the different installation sites.

Interior

For indoor LED strips, it is important to choose an aluminium profile that matches the interior and provides adequate heat control.

Outdoor facilities

Outdoors, LED strips are exposed to weather conditions such as rain and frost. Choose an aluminium profile that is designed for outdoor use and protects the LED strip effectively. It’s usually cooler outside and there’s more air circulation around the aluminium and a stronger wind to help with cooling.

Service and maintenance of Led strip lighting and aluminium profiles

The maintenance of LED strip lights and aluminium profiles is important to ensure that they work efficiently and last for a long time. Here are some tips on how to service and maintain them.

- Cleaning: keep the LED strip lights and aluminium profiles free of dust and dirt. Clean them regularly with a soft cloth or brush.

- Wiring and connections: check that the wiring and connections of the LED strip lights are in good condition and tightly in place. Loose connections can cause low light output or even damage to the LED strip.

- Moisture control: moisture can cause problems for led strips and aluminium profiles. Make sure the installation site is dry and well ventilated. For outdoor use, use outdoor aluminium profiles and LED strips, which are more resistant to moisture and weather conditions.

LED strips designed for special applications

Led strip lights are available in a wide range of special applications that do not necessarily require an aluminium profile. For example:

- Water resistant NEON led strip lights: water resistant NEON led strip lights are especially suitable for damp areas such as bathrooms where it encounters water all the time or outdoor areas. They are designed to withstand moisture and water, but special care and manufacturer’s instructions should be taken when installing them. NEON strips have lower power LED strips and should be installed outside where the outdoor air cools the LED strip.

- Low heat LED strip lights: in some places, such as museums or galleries, it is important to use lighting that produces as little heat as possible. Low heat output LED strips are suitable for this purpose and can be used in combination with aluminium profiles specially designed for thermal management. Lower power = lower heat.

Summary

The use of Led strip lights with aluminium profiles is an effective and elegant way to illuminate different spaces. To the question “Why does the LED strip light need an aluminium profile?” there is an obvious answer. Aluminium profiles help to control heat, protect the LED strips and make installation quick and easy. By choosing the right LED strips and aluminium profiles, you can create a functional and beautiful lighting solution for both indoor and outdoor spaces. Explore the different options and choose the products that best suit your needs to get the best possible results.

Frequently asked questions

How do I know which LED strip light is best suited to my needs?

Find out about the different types of LED strip, their light output, colour temperature and other characteristics. Compare them against your needs and budget to find the best option.

Can I install an LED strip light without an aluminium profile?

Although the LED strip can be installed without an aluminium profile, we recommend using one, as it will extend the life of the strip and give the lighting a neat appearance. In addition, the aluminium profile helps to control heat, which is important for the efficient operation of led strips.

How can I make sure that the aluminium profile is the right size for the LED strip light?

Check the dimensions of the LED strip and the aluminium profile before purchasing. Most manufacturers indicate the size of the LED strip for which their profile is designed. Also make sure that the internal dimensions of the profile are large enough to accommodate the LED strip and any wires.

Can aluminium profiles be cut to the right length?

Yes, most aluminium profiles can be cut to the desired length. However, check the manufacturer’s instructions, as some profiles may require special tools or methods for cutting.

Is it difficult to install aluminium profiles?

The installation of aluminium profiles is usually quick and easy. In most cases, you will only need the fixings and screws that come with the profile or other fixing accessories. Installation instructions can usually be found on the manufacturer’s website or on the product packaging.

Led strip lighting specialist

LedStore has been a specialist in Led strip lighting since 2010. We have our own product design, so our products are technologically state-of-the-art.

We focus on light colour temperature controlled and high colour rendering index lights. We do around 500 lighting designs in a year.

We offer a service of custom made led strips, i.e. custom made led light strips in profile. Also installed.

Remember that we are always ready to offer our help to you along the way, by email (myynti@ledstore.fi) and by phone (045 251 4510). As always, feel free to share photos of your own projects on social media at ledstore.fi at Instagram and ledstore.fi at Meta. We love to see the cool things done by our LEDs, and it also helps to provide inspiration for those who are not sure about the power and awesomeness of LEDs. Did you know that we already have over 3500 pictures of our LED installations in our Gallery!

Led Lights Gallery:

Product gallery: Pictures of products in different installation locations

Indirect light: Indirect light in different spaces

Room-specific: Light in different rooms

References: Complete houses that have been photographed